|

This page will attempt to deal with mast tabernacles mast step hinge plates, mast step plates and related matters - like halyard turning block systems. As usual, we start chronologically with the first contribution to this topic. An important read related to this page is Mast Stepping. Click here to go there

*************************

November 24, 2008. Below are pictures of Mike Zint's recently purchased Grand Finale's mast base and tabernacle. He posted a question on the Forum, and since neither of us can figure out how to post his pictures on the Forum it seemed best to post it here, starting a Technical Page on mast hinges and tabernacles. Here is his question posted Nov 24, 2008 in the Forum's Technical Section.

Ron's recent compliation of articles about raising masts on Dolphins was great. Now for a question about the small details. My mast tabernacle has a slot for the bolt to pin the mast in place and the mast itself has two holes for the bolt to pass through. Do you place the bolt through the lower hole in the mast to allow the mast to piviot then pull the pin and allow the mast to drop down and rest against the base plate of the tabernacle then move the bolt to the upper hole location in the mast?

Beautiful boats and fair winds!

Sailinmike

Dolphin #300

|

| |

Note the uneven cutoff at the bottom, and what looks like a pressure detent by a washer around the lower hole and maybe what might be a pressure point at the top of the same hole.

If anyone has an answer to Mike's question please post it on the Forum as a reply, or email to Ronbreault@dolphin24.org and we will get it up here. When your webmaster has a chance we will add information on Passage's and Marionette's Mast Hinge plate systems.

Webmaster Note: March 14, 2016 - it took a while but Mike has dealt with this problem. Here is his email and photos

Hi Ron,

I got to the point of raising the mast for the measurements required for my new main sail which is on order with Precision Sails when we discovered the existing mast tabernacle wouldn't let the mast pivot much past a horizontal position ( about 10 degrees) with the bolt installed. So I ordered a new Dwyer mast tabernacle designed to pivot. (photo below right - click here to go to Dwyer's mast hinge page)

Click on the photos for a larger image

In removing the old mast tabernacle the top layer of gelcoat and fiberglass came off too. (photo above left). Gotta love 3M 5100! The glass repairs are complete except for the gelcoat. I'm paying the price schedule wise now after taking 10 weeks off in December for much needed back surgery. My back is 20 years better now, but my free time is jammed up playing catch up on clients jobs that were put on hold. It's a shame because the weather here is perfect for working on the boat.

Mike

*******************************

November 29, 2008 Eric Varty, Canopache, Yankee # 188 sent in a picture of his interesting looking mast hinge plate and some comments about Mike's Zint's problem above.

Hi Ron,

Interesting question raised. Attached is pic (poor whit balance photo) of Canopache's step. Quite different arrangement that allows pivot of the mast on one clevis pin and attachment of a second to secure after raising. I do not have a pic of the bottom of the mast and since the boat is in storage in MA and I am in FL won't be able to provide one until spring. I recall that it is flat cut with a hole to exit wiring from the mast somewhat above the nylon plug over which the mast is set. The mast is held down in place and secured to the boat only by the stays and shrouds.

I wonder if the mast bottom in question has been shortened. If the bottom were corroded or damage the previous owner may have shortened the mast the distance from center to center of the holes and drilled a new hole further up the mast. The lower hole looks to be worn and the upper in more pristine condition. This would cause the stays and shrouds to be shortened. Are there swaged fittings or mechanical on these parts? If mechanical this would support this idea.

I do not believe that from the pics there appears to be enough clearance for the mast to pivot when attached to the step with the bolt (unless the distance from the bolt center when at the top of the slot in the step is equal to or larger than the diagonal distance from the center of the lower bolt hole on the mast to the bottom foremost or aftermost point on the mast [hard to describe] .

Eric

Canopache's Mast Hinge

*********************************

November 30, 2008 David Baumer sent in several pictures of his Aeyla Makaira, Yankee # 81's hinged mast plate with comments. They are repeated here below.

Mast step arrangement of Yankee Dolphin # 81 in March of 2008

I am betting the hinging mast step on Yankee Dolphin 81 is original equipment. I took the accompanying photographs to document its condition and construction as I plan her restoration. Note the arrangement in the photograph I took before I bought the boat.

At the base of the mast is a cast aluminum step that is screwed to the top plate of a hinge oriented on the boat to fold aft. The step is screwed to the top plate of the hinge with four stainless flat head machine screws. The base plate of the hinge is tapped for the screws. The top plate of the hinge is constructed from a 5” x 7“ stainless steel plate with the corners rounded. The after edge of the plate is ground to a 45 degree angle and two pieces of stainless tubing 1” inch long are welded to it from both sided along the outside edges. This creates the top plate of the hinge. The short lengths of the stainless tubing, I assume, are designed to reduce friction when its time to tap the pin out. Note the corner is broken off next to one of the screws that fasten the step to the hinge, and I am looking for a new step and/or wondering if I can weld to cast aluminum?. YES Between the top plate of the hinge and the cast aluminum mast step is a piece of what looks like thick black Mylar. At the base of the mast is a cast aluminum step that is screwed to the top plate of a hinge oriented on the boat to fold aft. The step is screwed to the top plate of the hinge with four stainless flat head machine screws. The base plate of the hinge is tapped for the screws. The top plate of the hinge is constructed from a 5” x 7“ stainless steel plate with the corners rounded. The after edge of the plate is ground to a 45 degree angle and two pieces of stainless tubing 1” inch long are welded to it from both sided along the outside edges. This creates the top plate of the hinge. The short lengths of the stainless tubing, I assume, are designed to reduce friction when its time to tap the pin out. Note the corner is broken off next to one of the screws that fasten the step to the hinge, and I am looking for a new step and/or wondering if I can weld to cast aluminum?. YES Between the top plate of the hinge and the cast aluminum mast step is a piece of what looks like thick black Mylar.

Securely fastened to the cabin top is the base plate of the hinge. It’s also welded up from ¼” stock. The bottom plate (5” x 7"x 3/8”) is constructed by welding triangular tapered flanges along sides of the after end (4 - ¼” long and 1 ¼” at their widest point). The flanges run past the after end by 3/16 of an inch. The flanges are drilled to accept the ½” pin. The stainless steel pin is ½” in diameter, 6” long, and has holes for cotter pins to keep it in place.

Key dimensions of hinge plate above

****************************

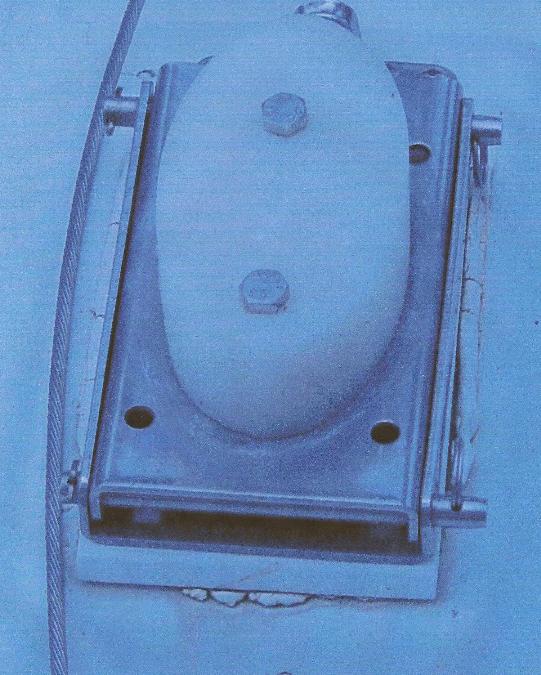

November 28, 2009. Keith Gross sent in the following email and pictures of Cats Paws, his Pacific Dolphin # 279's hinge plate and mast butt. Standardization of these things were not high priority...

Ahoy Cap'n Ron,

I was in the Technical Section looking around and noticed the mast/step section. Cats Paws step is different than any shown. It's 6" long, 4-3/4" tall, and 3-1/2" wide. The slot runs from 1" to 3-1/2" (all inside measurements). Her mast is 3-1/4" by 5", with the hole 2" up from the bottom. Above are a few pictures.

Later, Keith

**************

April 17, 2011. Joe Sharpe, Yanqui, Yankee #197, posted a question on the Forum regarding the 'hump' on which the mast plate sits. Erik Evens, Robin Lee, Yankee #118 responded. Here is their exchange

Have any Yankee owners removed the mast step fitting? It is held on by bolts above, of course, but I can't see any access to the underside (in the cabin) where I might get at nuts. It sits on that big fiberglass "hump" and I'm almost wondering if it's in there with lag screws.

I want to remove it to place a plate underneath providing attachment points for turning blocks. I'm hesitant to just go unscrewing away, though.

Thanks for any insight,

Joe

**********************

Hi Joe-

On Robin Lee (Yankee #118), I have a bare fibreglass headliner, since any wood veneer which might have once covered it has long-since been removed. There are no fasteners coming through the liner in the area of the mast step.

I think that the "hump" must contain a large chunk of wood, molded into the deck at the time of manufacture. Anything fastened to the "hump" must be attached with lag screws.

On Robin Lee, there was a large pad eye attached to the aft face of the "hump", which looked to be fastened to it with two bolts. I presume it was original hardware. I say "was", because I naively attached a boom vang to the pad eye, and proceeded to rip it out of the deck. It was attached with two lag screws.

That's all I know! Any further knowledge will need to come form a forensic autopsy of a Dolphin-to-be-demolished or a Dolphin-to-be-rebuilt.

By the way, on Robin Lee, we have the halyard turning blocks directly lagged into the hump. So far, no failures... seems plenty strong. Here's two photos that show it (kind of):

Best-

EKE

To see Eric's (kind of) pictures click here to go to the Forum post. We found a good photo of Robin Lee's set up in our archives.

*******************

April 18, 2011. Jonnie Walker, Yankee #227 confirms the bolts are lag bolts.

***********************

June 18, 2011. On the subject of bolts and screws for the mast hinge plate or tabernacle - a interesting Forum comment on why lag screws not bolts

Forum: Technical

Topic: Yankee Dolphin mast step

Posted By: ChuckD

Actually since the mast step/tabernackle is in compression, lags are all that are needed. With a dismasting, the lags would pull out, through bolts may take the cabin top with it? S&S knows more about it than I though, they spec'd out for lags for a reason

just my .02c

cheers

*********************

June 5, 2012. Carl Hazelton, Miss Behavin', Yankee #248 had some replacement chainplates made up by a Corpus Christie area fabricator/welder named KELMO June 8, 2014 update - now out of business

**************************************

July 1, 2012. Here a couple more mast steps

The mast base plate on Marionette does not 'pin' to the boat's mating maststep plate. Instead, it simply rests on the cross pins, held there only by the downward pressure on the shrouds - like some dinghy masts do. Stan Secora (Jato), a marine architect once told your webmaster that this might be a good idea - if one ever had a rigging failure at sea and the mast went overboard it would not take a significant part of the wooden coach roof with it!

*************************************

August 16, 2013. Here is a photo of Fred Gougen's Pacific Dolphin #261's mast step/tabernacle

For more pictures, and the story on Thankful's mast raising set up - click here

*******************************************

March 11, 2014. Jerry Slaughter has been working on restoring ROWDY, Marcot/O'Day #5. Here is his mast step (email excerpted from ROWDY's home page

The mast hinge plate/step is attached. I've included a couple of photos.

Click on the photos above for a large view

The bottom plate, 1/4 inch aluminum, is bolted to the cabin top and pinned to the top plate which is screw attached to the old mast fitting. This set up is very similar to that of Yankee #81, AEYLA MAKAIRA. The mast fitting was pretty beat up by the boat yard when they were trying to de-rig her in New York. Also, the casting was fairly rough. The machine shop did some welding and then built up and faired the base so it would sit flat on the hinge plate.

***********************************

August 19, 2019. Carl Harrington, Yankee Girl Esther, Yankee #89, had a 'little' problem with taking down his mast. He posted on the Dolphin24 sailboats Facebook page and followed up with an email and photos. We'll put this up in our Technical Section as well. Click the following link to go there http://dolphin24.org/mast_tabernacles_hinges.html

Carl Harrington

August 12 at 8:43 PM

Anyone know what the mast step “hump” is made of for a 1968 Yankee built Dolphin 24? When using a gin pole to lower the stick, things went great until the mast shifted to starboard in the last 6 feet and ripped the hinge out of the step. Oh well, probably been there since ‘68.

Webmaster reply - Ron Breault Ouch! Send me a pic, Carl, and I'll get your question up on the dolphin24.org website

Ron-

Per my FaceBook post, here are pix of my mast step arrangement. I think the built up step is wood inside, but hope for confirmation from the brain trust. It spans between two bulkheads/deck beams. When lowering, the mast was fine till the last six feet, when it moved to one side, pulled the four wood screws out, and bent the step hinge. Now the repair list includes fixing the step, new VHF antenna, new masthead light, and Windex. Ugh.

Thanks for sharing with the community.

Carl

Click on the photos for a larger image

***************************************

|