|

July 1, 2011. Over the years there have been various comments about thru hulls by owners on their individual boat pages. Here we will, over time, try and collect them. We'll start with Clinton Hodges' comments about his restoration project on Windswept too, Yankee #245.

Hi Ron,

Windswept too's refit continues, and is going well. Except...and I don't care to use that word. However, I must, and here's the conundrum I'm facing.

In above picture are two thru hulls. The one on the left is a 3/4 ", silicon bronze, flush-thru hull, with a flange diameter of 2 9/16", or 65mm. The thru hull on the right has a flange diameter of 1 15/16, or 49mm.

If I can't locate a used 3/4" thru hull of a flange diameter of 2 9/16", I don't see many options except to braze the threads from a new thru hull to the balance of threads on the old flange, or to totally glass over the hole.

Off the top of your head, do you know of used marine parts stores that might possibly have a bin of used thru hulls???? Webmaster Note: For used marine stuff I hunt around but my favorite place is in Wickford, RI. They have an online catalogue. http://marineconsignment.com/boat-parts/ There are others on line. Good luck

I wouldn't be in this situation if it wasn't for the under-the-sink thru hull being directly connected to a thru valve instead of a seacock. Strange as it is, a thru valve costs nearly as much as a flanged seacock, so I wonder what the reasoning was back then? $ probably. The cockpit drain has a similar, but larger 1 1/4" valve. Could it have come from Yankee Yachts this way? My understanding is that thousands of sailboats are plumbed in this incorrect manner. So it's anyone's guess how many sailboats sit on the bottom of the ocean because an improper valve was used on a thru hull.

Regards, Clinton Hodges

***************

August 3, 2011. Your webmaster and Jonnie Walker, Yankee #227 had an exchange of emails regarding thru-hulls and invite additional comments. Minor edits

Hi Ron,

I'm going to remove the through hulls for the head as we have had good experiences with composting heads, this leaves me with two holes under the waterline....I don't have any problem with the sink drain because it has a seacock on it to close it....but the cockpit drain makes no sense to me.

In mine....(I don't know if others are different)...the drain comes out of the forward section of the cockpit and goes almost straight down to a through hull with a seacock on it. Here is my problem......

If I leave the boat, and I close the seacock the cockpit will not drain. If I leave it open I am reliant on the hose which I know some day will fail. Maybe I am over sensitive, but I don't like holes under the waterline. Has anyone else worried about this?

I'm thinking about moving the through hull aft and up above the waterline and piping the hose there.I havent done any measuring to see it there really is enough room but looking at it I'm pretty sure it will be close.

-j

*******************

Hi Jonnie

Marionette has the same set up you do - 2 drains on the cockpit floor at the forward corners. They drain straight down through hoses that connect to thru hulls - no sea cocks. My hoses are 'heavy duty' reinforced rubber exhaust type hoses fastened with ss hose clamps. I worry about them but as far as I can tell they are going to outlast me. I worry more about possible corrosion of the thru hull pipe that is inside the hose - I can't see it. Once I tried to take off the hoses and I could not budge them....On the outside of the hull the thru hulls looks perfect. So, I forget about it until guys like you remind me.

Also, those drains need to be left open as otherwise you risk flooding the cockpit from some freak wave, heavy rain, maybe then ice and freezing...etc. This has always puzzled me. A seacock usually makes sense, of course. But when it is part of a 24/365 drain system - a sink or head drain are not - the skipper is not on board 90% of the time to close the seacock if there was a failure. If you leave the boat at a slip or mooring with closed drains for a few days the cockpit can fill from heavy rain, maybe flood through the companionway slides, fill the boat and you have a big problem... Maybe the better solution for these particular drains is a strong thru hull/hose/clamp system and regular inspections which is probably why they were done that way in the beginning?

These comments have not been cleared by legal....

Ron, Marionette, #12

*******************

Back on April 23, 2011 your webmaster had a conversation with Jim DeMeola, Yankee #90. Here's the excerpt

Three weeeks ago the hose for one of the cockpit drains failed and the boat sank at the dock. She was raised last week and there was not much damage - its cold, fresh water - the sails, cushions and motor were not on the boat. One of the bow chocks pulled out, and for some reason the centerboard wire parted. The boat is dried out and will be hauled in a few days.

************** hmmmm **************

There are some interesting comments and pictures of fittings by David Baumer, Yankee #81 in his restoration report http://www.dolphin24.org/aeyla_summer_report.html

*******************

July 16, 2012. So, its over a year since we followed up on this subject. Have you checked your thru hulls lately? Alden Harris, Pacific Dolphin #263 did

|

|

|

valve out |

Yikes! |

looks much better |

Clinton Hodges (Windswept too, Yankee #245) saw the photo and sent in the following emails (consolidated) and an informative link.

|

Hi Ron,

That's a nasty looking valve on Alden's Dolphin. This link: http://www.groco.net/SVC-MAN-07/Sec4/PDF/IBV-FBV-TB.pdf will give Alden and other Dolphin owners some idea of what the thru hull/valve connection should should look like.

I debated back and forth as to whether or not to go with full-on silicon bronze flanged seacocks or to go with the Groco flanged base adapters and Forespar Marelon thru valves; the silicon bronze set-up is heavy and puts a lot of mechanical leverage on the threaded portion of the thru hull which isn't desirable.

The picture is a mock-up of the thru hull/seacock system I will be using on Windswept too. The thru hull, backing plate, and Groco flanged base adapter will be permanently installed. All that is required is to install the valve and barbed tip is a suitable marine sealant. It's important to use the proper marine hose and double SS non-perforated hose clamps.

The backing plate can be made of FRP or marine plywood which is what I'm using set in 3M 5200. Some may prefer to glass the backing plate in. I used several coats of West System Epoxy to coat the first two of four backing plates and this will keep things good and dry for many years to come.

One other note, I failed to mention in previous posts is that Yankee Dolphins appear to have backing plates for thru hulls in the form of a built-up mound as part of the mold. The protruding mound around the thru hull opening is pronounced and should be taken into account when preparation and fitting the backing plates to the hull.

I hope this information comes in handy.

Regards,

Clinton Hodges

s/v Windswept too

|

************************************************

June 14, 2014. We got an email from Lon Zimmerman, Yankee # 246, Blue Dolphin

I JUST FINISHED READING THRU THE COMMENTS ON THRU HULLS. BLUE DOLPHIN'S THRU HULLS LOOK LIKE SOME OF THE BAD PHOTOS POSTED. I PLAN TO ELIMINATE THE TOILET THRU HULLS AND USE A COMPOSTING TOILET.

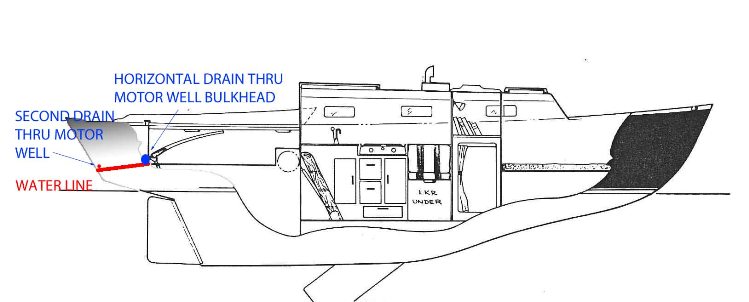

HAS ANYONE TRIED PUTTING THE COCKPIT DRAIN VERTICALLY AT THE REAR OF THE COCKPIT SO IT WOULD DRAIN TO THE OUTBOARD WELL? THE FLOOR IN THE OUTBOARD WELL SLOPES DOWNWARD AND AFT AND THERE IS ALREADY A DRAIN OPEING AT THE AFT END OF THE MOTOR WELL. I HAVE SEEN THIS DONE ON MONTGOMERY 17s AND IT WORKS WELL.

I PUT A LEVEL ON THE COCKPIT FLOOR OF MY BOAT AND IT SHOWED IT TO BE LEVEL. IT MIGHT BE POSSIBLE TO CAUSE DRAINAGE IN COCKPIT TOWARD THE MOTOR WELLDIAGRAM BELOW TO SHOW REAR COCKPIT DRAINS INTO MOTOR WELL.

LON

PORT TOWNSEND

Click on image for a larger view

Webmaster Note: The cockpit drain thru hulls issue is one of my favorite worries. Marionette has a different type of transom well but that's no excuse. More comments from readers are solicited.

June 17, 2014. Clinton Hodges, Yankee # 245, Anchorage, Alaska, comments on Lon's idea of moving his cockpit drains to the rear of the cockpit.

I visit Windswept too regularly at the marina even if not sailing her and yesterday was no different except it had rained a little the night before, and with the cockpit drain closed there was a very small amount of water in the cockpit; about four pumps took care of that.

I was thinking about Lon Zimmerman's post (YD #246) regarding moving the cock pit drains aft and I just want to pass on this observation. Windswept too lightly loaded and a four horse motor in her transom well, water in the cockpit runs forward to the existing cockpit drains. Thus, Lon’s idea of repositioning the drains may not work. I just wanted to pass this on as he may want to put 246 in the water before making his modifications.

******************************

June 18, 2014 Lon Zimmerman responds

HI RON AND CLINTON,

COINCIDENTALLY -- NOT ONLY ARE OUR BOATS CLOSE, I ALSO LIVED IN ALASKA FROM 1974 UNTIL 2007 . I WAS A SECONDARY SCIENCE TEACHER IN THE BUSH AND FINALLY WITH THE ANCHORAGE SCHOOLS. I HAVE SAILED ON BIG LAKE, ALSO THRU THE INSIDE PASSAGE.

MY BOAT IS STILL SITTING IN THE WATER HERE IN PORT TOWNSEND , WAITING FOR HAUL OUT THIS THUR.

THIS MORNING IT HAD RAINED AND ON MY BOAT (4 HP TOHATSU) THE WATER WAS POOLING TOWARD THE AFT END OF THE COCKPIT. WHEN I CHECKED THE BOAT WITH A LEVEL THE OTHER DAY, IT WAS LEVEL. OF COURSE, I WAS STANDING IN THE BOAT LOOKING AT THE LEVEL, SO ONE MIGHT INVOKE THE HEISENBERG UNCERTAINTY PRINCIPLE.

I THINK THE COCKPIT IS DESIGNED TO SEND WATER TO THE GUTTERS , EITHER SIDE, BUT WHETHER IT MOVES FORWARD OR AFT MAY BE UNIQUE TO INDIVIDUAL BOATS.

I SUSPECT THEY PLACED THE DRAINS IN THE FRONT OF THE COCKPIT BECAUSE IT IS HANDY TO REACH THE THRU HULL VALVE AT THAT POINT. THE WATER IS AS LIKELY TO MOVE FORWARD AS BACKWARD, THE NATURAL ROCKING OF THE BOAT WILL EVENTUALLY LEAD IT TO THE DRAIN.

I AM TEMPTED TO PLACE A DRAIN IN THE GUTTER AT THE AFT END OF THE COCKPIT AND DO AWAY WITH THE TWO FRONT DRAINS. THAT SCUPPER COULD LEAD DIRECTLY OUT THRU THE STERN ABOVE WATERLINE. WE COULD UTILIZE THE FRONT DRAINS THIS WAY , EXCEPT FOR THAT COLLECTOR BOX WHICH BRINGS US CLOSE TO WATERLINE.

LON

September 23, 2014. We have the following update from Lon on his thru hulls (edited).

ON THE COCKPIT DRAINS I SIMPLY GLASSED OVER ALL UNDERWATER THRU HULLS AND PUT THE COCKPIT DRAINS AT THE WATER LINE. I CROSSED THE CONNECTING HOSES -- SO THE PORTSIDE DRAIN CONNECTS TO THE STARBOARD THRU HULL. THEY DRAIN JUST FINE. I FILLED THE COCKPIT WITH WATER TO GIVE THEM A TEST.

LON

|